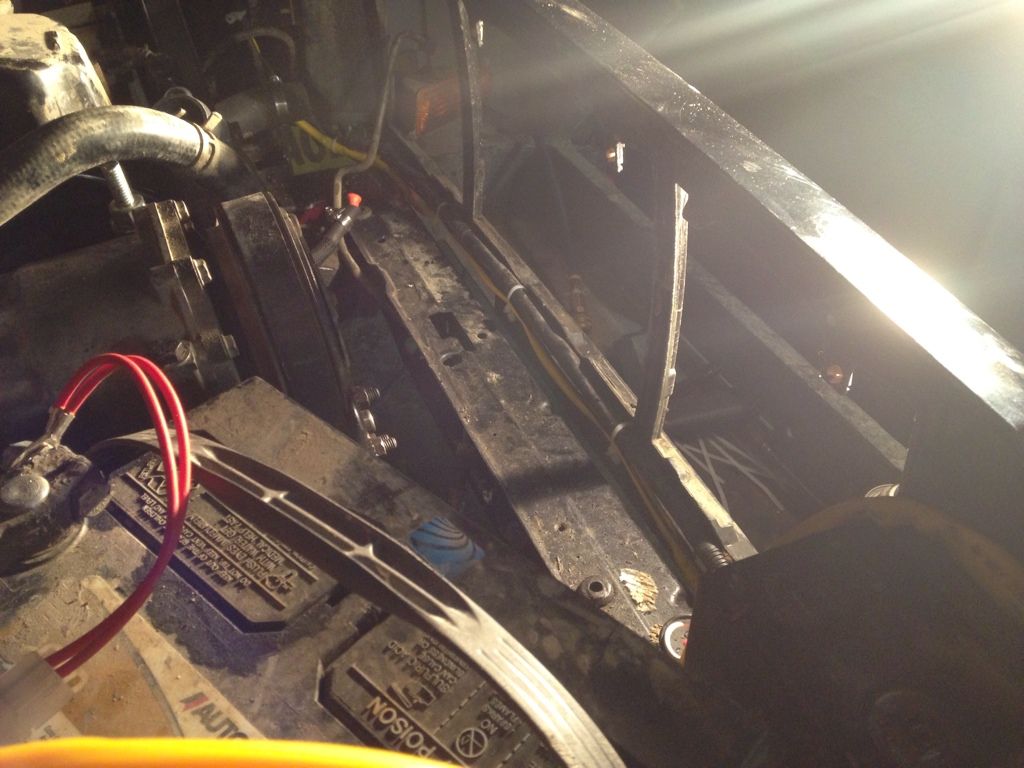

Another update on my on board air progress. Got 20' of 3/8 air hose today.

The build thread i was reading called for 300PSI tube. I ended up with 1,125PSI hose. I guess you could say mine is a little bit stronger than his is going to be.

I also got an air filter and a pressure gauge that goes up to 160PSI. I plan on running my system at around 140-150PSI. Should of got a gauge that went to 200PSI, but whatever.

Also got (2) 3/8" Apollo ball valves. Going to put a dirt leg on the piping to get rid of all of the condensation in the system. This wasn't called for in the thread, but it's what you do when you pipe an air system into a shop. Figured i might as well do it.

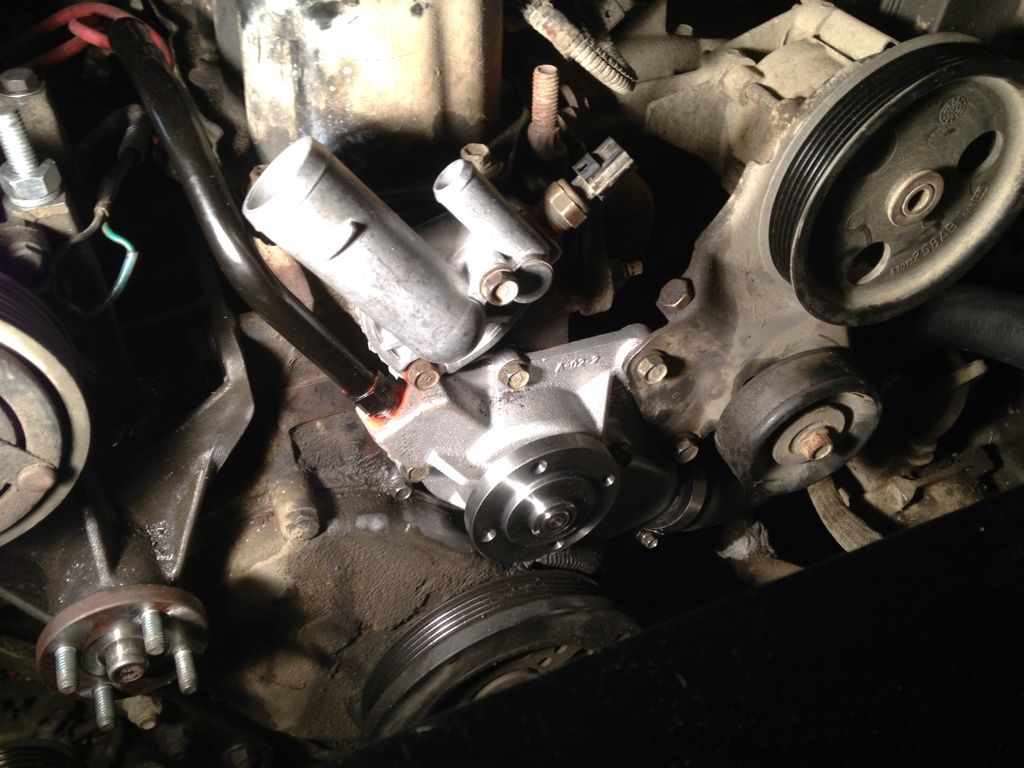

It appears that most sanden compressors have 1/2" NPT threads coming out the back. Mine doesn't. Instead, I'm going to cut them square where the red lines go across, and weld on a 3/8" nipple to each side. This way i will have something to thread into, and i don't have to "slide the air hose over the metal and hose clamp it on". I just think it'll be stronger.

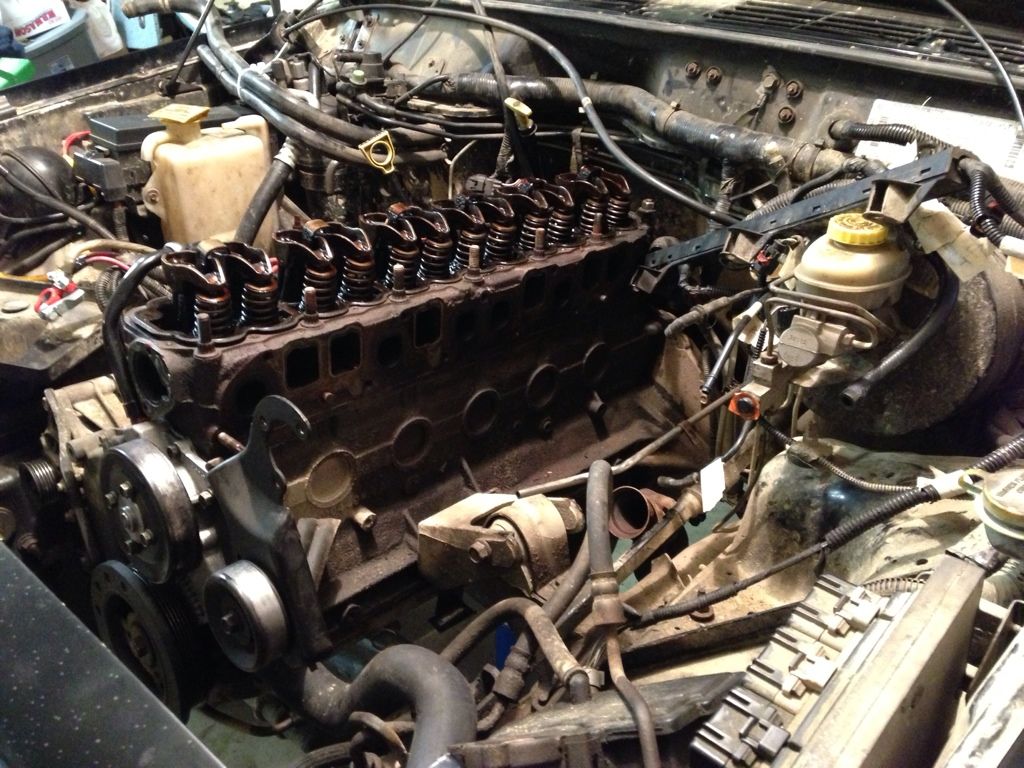

As for keeping this thing lubricated, i began to read up on it, and it's like i've opened a can of worms. Nobody can decide if greasing it or oiling it is better, and no one really explains how either are done.

I think i put an inline oiler in the front, and just keep filling it with A/C oil as it calls for it. I then realized that on the bottom of my air filter there was a self bleeder. Maybe i'm suppose to put a hose coming off that and feed it back into the inline oiler? I don't know. Time will tell.

The other thing i don't know is where do i wire the pressure switch to? Do i wire that to the compressor to tell it to kick off or what? I have no clue how to wire any of this up. Need to find a thread on that soon.

I'll keep you all updated with pictures.

The build thread i was reading called for 300PSI tube. I ended up with 1,125PSI hose. I guess you could say mine is a little bit stronger than his is going to be.

I also got an air filter and a pressure gauge that goes up to 160PSI. I plan on running my system at around 140-150PSI. Should of got a gauge that went to 200PSI, but whatever.

Also got (2) 3/8" Apollo ball valves. Going to put a dirt leg on the piping to get rid of all of the condensation in the system. This wasn't called for in the thread, but it's what you do when you pipe an air system into a shop. Figured i might as well do it.

It appears that most sanden compressors have 1/2" NPT threads coming out the back. Mine doesn't. Instead, I'm going to cut them square where the red lines go across, and weld on a 3/8" nipple to each side. This way i will have something to thread into, and i don't have to "slide the air hose over the metal and hose clamp it on". I just think it'll be stronger.

As for keeping this thing lubricated, i began to read up on it, and it's like i've opened a can of worms. Nobody can decide if greasing it or oiling it is better, and no one really explains how either are done.

I think i put an inline oiler in the front, and just keep filling it with A/C oil as it calls for it. I then realized that on the bottom of my air filter there was a self bleeder. Maybe i'm suppose to put a hose coming off that and feed it back into the inline oiler? I don't know. Time will tell.

The other thing i don't know is where do i wire the pressure switch to? Do i wire that to the compressor to tell it to kick off or what? I have no clue how to wire any of this up. Need to find a thread on that soon.

I'll keep you all updated with pictures.

Comment