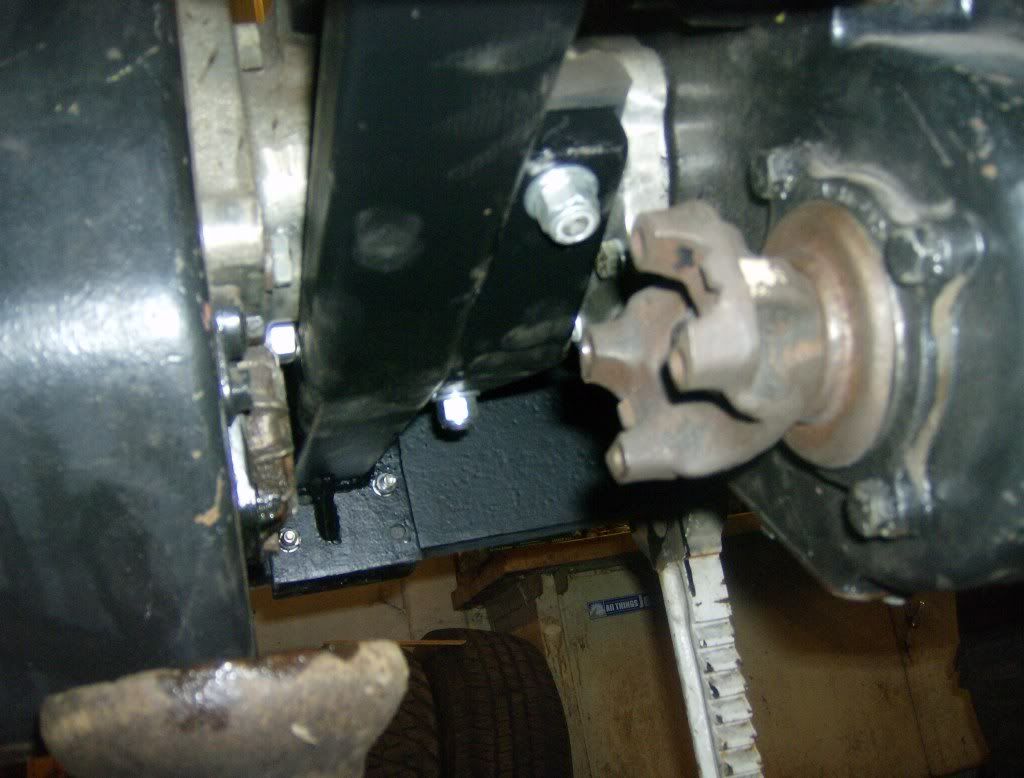

Here is how bad the axle wrap was. I ripped it around the parking lot at my shop a few times. My friend said the pinion would twist almost 90 degrees when I would get on it, making the driveshaft bind, as you can see here. The binding mashed the Ujoint caps on the 14 bolt yoke

Prep axle

Plasma cut off the perches that helped the jeep move .03 miles

Smooth

Next, I wanted to set the axle back up to see what my new wheelbase is going to look like. The jeep was at 97" before, I am going to 102". Someone told me that is too long, but I do not agree.

Removed the rear bumper and I am going to move it back. It has a pretty good departure angle now

Next thing I have to do is redraw my 4 link design and start making my truss/ upper link mounting points

Prep axle

Plasma cut off the perches that helped the jeep move .03 miles

Smooth

Next, I wanted to set the axle back up to see what my new wheelbase is going to look like. The jeep was at 97" before, I am going to 102". Someone told me that is too long, but I do not agree.

Removed the rear bumper and I am going to move it back. It has a pretty good departure angle now

Next thing I have to do is redraw my 4 link design and start making my truss/ upper link mounting points

((

(( plasma cutter

plasma cutter

2000 XJ with goodies soon to be in pieces

2000 XJ with goodies soon to be in pieces

Comment