Goal: an all around trail truck, built for heavy abuse. Ultra 4 in spirit, deff not in motor though, cause i'm a poor bastard. But, I am building it light, sleek, lots of uptravel and a super low stance. The plans with this are to run the RCrocs Race series in 2012.

Started life as an 88 yj, now its cut, alot.

Specs

Drivetrain:

Ford Racing 302 with Painless Wiring Fuel Injection

Ford C6 transmission

Atlas 3.8, 2 speed, 1350 yokes, 32 spline outputs

Tom Woods Driveshafts

Axles:

Front- narrowed 65" wms HP Dana 60, Chevy outers, Superior 5.38 gears, Detroit locker, 35 spline chromolly everything from superior axle, CTM u-joints, 5x5.5 bolt pattern, Solid 35 spline drive flanges, fabricated double sheer high steer arms

Rear- 65" wms Solid Axle Semi-float LP Dana 60, superior 5.38 gears, ARB air locker, superior 35 spline axle shafts, 5x5.5 bolt pattern

Suspension:

14" travel Bilstein 9100 2.0" Body Coilovers with Remote Reservoirs and anti-cavitation valving

Double Triangulated 4 link rear

Triangulated 4 link front -- links utilize Currie Johnny Joints and yuppp square tube

Fox 2.0 Air Bumpstops

Designed around a 112" wheelbase with 8" of uptravel

Bypasses when i can afford them

Wheels and Tires:

39" Red Label BF Goodrich Krawlers

17" Walker Evans Aluminum Beadlocks 5x5.5 bolt pattern

Chassis:

designed and built by me, utilizes the middle section of the yj frame, from right in front of the motor mounts to where the rear 4-link starts.

1.75" .120 wall DOM

Narrowed Jeep TJ Grill

Misc:

PSC Double Ended Steering Ram and Orbital

CJR Power Steering Pump from RoushYates

Summit Racing 18 Gallon Fuel Cell

Ron Davis Radiator with dual Electric Fans

PRP Seats

Coolers for P.S. and transmission from B&M

Cooler for cold drinks between the two seats

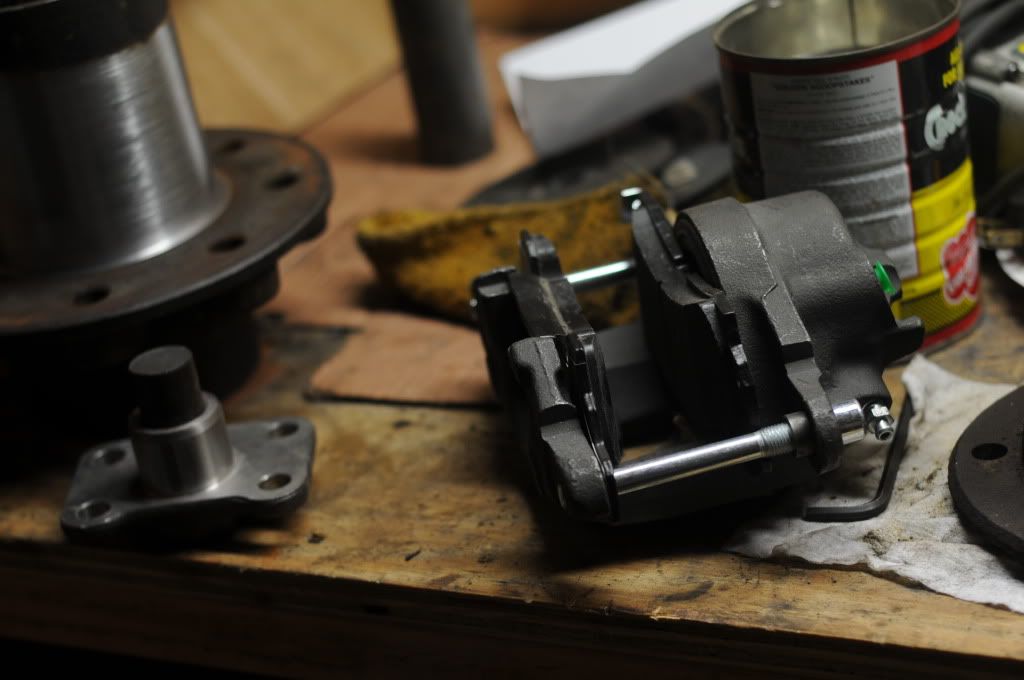

Wilwood Dual Master Cylinder brakes from Speedway Motors

CNC cutting brakes

And that's how she starts, pictures and updates to come as work progresses and its not raining.

Before I go any further I need to take a second to acknowledge the people and companies that without their help, this build and this truck, would not be possible.

- Adam and Clayton from Clayton Offroad

- Justin Williams from Custom Creations, LLC

- Phil Larocca of Gunsmithing Ltd, for tons of help in machining various parts, and some hubs already, thank you!!! will post bling pics of bling 60 hubs, when we finish them.

- Solid Axle

- Poly Performance

- Currie Enterprises

- Steve Usher, for getting me a smoking deal on tires

- Coors Light and my buddy Josh, who helped me total my XJ, therefore driving this project forward.

and last but not least, Mr. William Gentile of HMC, for his feverish support and uncanny motivation, (i'm actually doing it fucker

)

)

Started life as an 88 yj, now its cut, alot.

Specs

Drivetrain:

Ford Racing 302 with Painless Wiring Fuel Injection

Ford C6 transmission

Atlas 3.8, 2 speed, 1350 yokes, 32 spline outputs

Tom Woods Driveshafts

Axles:

Front- narrowed 65" wms HP Dana 60, Chevy outers, Superior 5.38 gears, Detroit locker, 35 spline chromolly everything from superior axle, CTM u-joints, 5x5.5 bolt pattern, Solid 35 spline drive flanges, fabricated double sheer high steer arms

Rear- 65" wms Solid Axle Semi-float LP Dana 60, superior 5.38 gears, ARB air locker, superior 35 spline axle shafts, 5x5.5 bolt pattern

Suspension:

14" travel Bilstein 9100 2.0" Body Coilovers with Remote Reservoirs and anti-cavitation valving

Double Triangulated 4 link rear

Triangulated 4 link front -- links utilize Currie Johnny Joints and yuppp square tube

Fox 2.0 Air Bumpstops

Designed around a 112" wheelbase with 8" of uptravel

Bypasses when i can afford them

Wheels and Tires:

39" Red Label BF Goodrich Krawlers

17" Walker Evans Aluminum Beadlocks 5x5.5 bolt pattern

Chassis:

designed and built by me, utilizes the middle section of the yj frame, from right in front of the motor mounts to where the rear 4-link starts.

1.75" .120 wall DOM

Narrowed Jeep TJ Grill

Misc:

PSC Double Ended Steering Ram and Orbital

CJR Power Steering Pump from RoushYates

Summit Racing 18 Gallon Fuel Cell

Ron Davis Radiator with dual Electric Fans

PRP Seats

Coolers for P.S. and transmission from B&M

Cooler for cold drinks between the two seats

Wilwood Dual Master Cylinder brakes from Speedway Motors

CNC cutting brakes

And that's how she starts, pictures and updates to come as work progresses and its not raining.

Before I go any further I need to take a second to acknowledge the people and companies that without their help, this build and this truck, would not be possible.

- Adam and Clayton from Clayton Offroad

- Justin Williams from Custom Creations, LLC

- Phil Larocca of Gunsmithing Ltd, for tons of help in machining various parts, and some hubs already, thank you!!! will post bling pics of bling 60 hubs, when we finish them.

- Solid Axle

- Poly Performance

- Currie Enterprises

- Steve Usher, for getting me a smoking deal on tires

- Coors Light and my buddy Josh, who helped me total my XJ, therefore driving this project forward.

and last but not least, Mr. William Gentile of HMC, for his feverish support and uncanny motivation, (i'm actually doing it fucker

)

)

Vice President of Internal Affairs at Dirty Donny's House of Hookers

Vice President of Internal Affairs at Dirty Donny's House of Hookers

Comment