From the factory most 4x4's arent really 4x4's. Only 2 tires have power to them at all times. Those 2 tires will be the tires with the least traction. A Locker is short for Locking Differential. It allows power to be distributed to both wheels on a rearend or front end. A limited slip can also be effective, but in comparison to a locker they suck, so I won't talk about them here.

What axle should I lock first?

This is probably the most commonly asked question pertaining to lockers. And alot of Variables come into play here, what is the right answer for someone, may be the wrong answer for another person. Generally speaking a rear locker will get you more places than a front locker, others may disagree with this, but it is what i have found in my experience. First off if you have a weak rear axle for the tire size you are running, (ie dana35 on anything larger than a 31" tire) it probably isnt a good idea to increase the stress on the shafts by adding a locker that that differential. Another soft spot which has many opinions is snow travel. People say autolockers will plow in the snow on the throttle, which is true, but if you know how to drive in the snow it is a non-issue.

What locker is right for me?

Well this depends. Much of it is personal preference. I will go through the currently available locker options and you will have to decide for yourself.

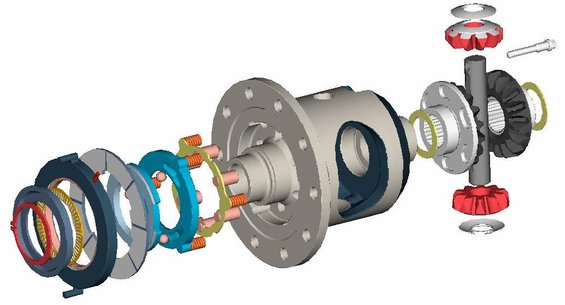

ARB AIR LOCKER:

This is a normally open air activated selectable locker. You will need an on board air setup to run it, which makes this one of the more expensive options. How it works is, Once you flip a switch on your dash, a quick burst of air is sent to the locker effectively making it a spool. Flip the switch again and you are back to an open differential. This locker replaces the factory carrier and requires air lines to be routed to it.

DETROIT LOCKER:

This is the king of autolockers, 100% traction when power is applied, and buttery smooth when going around corners. It is a full case locker meaning it replaces the factory carrier.

LOCK-RITE LOCKER:

This is the cheapest of lockers, but that doesn't mean it is bad. Its a simple autolocking type locker, when power is applied power goes to both rear wheels. There are reports of quirky street manners especially in short wheelbased rigs with soft flexy suspension. But everything is a tradeoff. This locker drops into the factory carrier and replaces just the spider gears.

AUSSIE LOCKER:

See lock-rite locker. This locker is virtually the same as the lock rite, but with a better warranty.

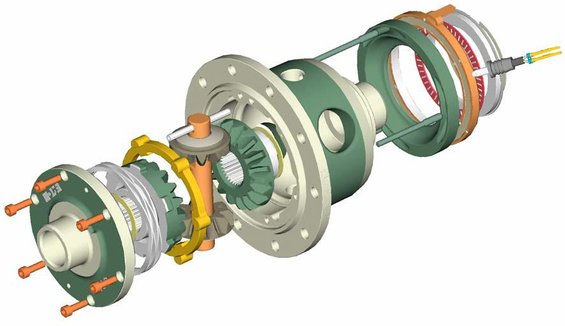

OX LOCKER:

This is a cable actuated selectable locker. comes with a very heavy duty diff cover which houses the shift fork and cable end for actuation. Disengaged it is an open differential for excellent street manners, and engaged it is a spool for 100% traction. You will need to also buy a cable the correct length for your application. This locker replaces the factory carrier. There are also now an air locker option and an electronic option for the ox locker.

LINCOLN LOCKER:

Weld yo spider gears and have a spool. do it right and you have cheap traction, do it wrong and you have exploded insides.

IM POOPED ILL POST MORE LATER

What axle should I lock first?

This is probably the most commonly asked question pertaining to lockers. And alot of Variables come into play here, what is the right answer for someone, may be the wrong answer for another person. Generally speaking a rear locker will get you more places than a front locker, others may disagree with this, but it is what i have found in my experience. First off if you have a weak rear axle for the tire size you are running, (ie dana35 on anything larger than a 31" tire) it probably isnt a good idea to increase the stress on the shafts by adding a locker that that differential. Another soft spot which has many opinions is snow travel. People say autolockers will plow in the snow on the throttle, which is true, but if you know how to drive in the snow it is a non-issue.

What locker is right for me?

Well this depends. Much of it is personal preference. I will go through the currently available locker options and you will have to decide for yourself.

ARB AIR LOCKER:

This is a normally open air activated selectable locker. You will need an on board air setup to run it, which makes this one of the more expensive options. How it works is, Once you flip a switch on your dash, a quick burst of air is sent to the locker effectively making it a spool. Flip the switch again and you are back to an open differential. This locker replaces the factory carrier and requires air lines to be routed to it.

DETROIT LOCKER:

This is the king of autolockers, 100% traction when power is applied, and buttery smooth when going around corners. It is a full case locker meaning it replaces the factory carrier.

LOCK-RITE LOCKER:

This is the cheapest of lockers, but that doesn't mean it is bad. Its a simple autolocking type locker, when power is applied power goes to both rear wheels. There are reports of quirky street manners especially in short wheelbased rigs with soft flexy suspension. But everything is a tradeoff. This locker drops into the factory carrier and replaces just the spider gears.

AUSSIE LOCKER:

See lock-rite locker. This locker is virtually the same as the lock rite, but with a better warranty.

OX LOCKER:

This is a cable actuated selectable locker. comes with a very heavy duty diff cover which houses the shift fork and cable end for actuation. Disengaged it is an open differential for excellent street manners, and engaged it is a spool for 100% traction. You will need to also buy a cable the correct length for your application. This locker replaces the factory carrier. There are also now an air locker option and an electronic option for the ox locker.

LINCOLN LOCKER:

Weld yo spider gears and have a spool. do it right and you have cheap traction, do it wrong and you have exploded insides.

IM POOPED ILL POST MORE LATER

Comment