This will be ongoing so bear with me. This is what I did during the day today. We didn't have a lot of jobs so my boss was like,"why don't you work on your Jeep?" Uh ok!

I have decided that I need some hot long arm action. I will incorporate Unibody stiffeners in my build. I also bought some 4.5" RE coils, 22" brake lines, and 4 RE 4.5-5.5 shocks. That should all be here on the 10th. Im still waiting on parts from extremecrawlers.com.

Here is how far I got today.

Here is the unibody stiffener. I am going to weld nuts to the inside on the sides and bottom to bolt the crossmember to. These took all of 15 minutes to make. I did everything free hand with my plasma cutter. I used a press to bend it up. I am going to use a hole saw to make holes to weld through and stitch the edges.

Next I took out the stock crossmember and started to build the replacement. Keep in mind there is no finish work. I didnt have my grinder and its all free hand plasma work. It will attach with 4 bolts on the bottom and 2 on the sides.

I still have to make end caps with holes for access and weld it up. Still deciding on TIGing the whole thing or just MIG it...

Here is how it fits. Nice and snug.

Next is a pleasant suprise. Well not totally but I didnt think it was that bad.

I have to pull the interior and get it all welded up. Thats gay.

This is what will be my long arms as soon as my Johnny joints, inserts and bushings get here. 2x.250 square for lowers and some 1.5x1.25 square for uppers.

Here is 100 ft of 1.75x .120 CREW that will end up as my bumpers.

Employees that helped today.

Here is the old shop whore. Still works like a champ.

Ah and my new friend.

So plug weld the stiffeners in, make some control arms brackets when my joints come in and then finish the long arms. After that I will be cutting out my rockers and putting 2x6x3/16 in its place.

Had some time today to do a little more. I cut the holes for the unibody stiffeners to weld through. My hole saw has requested a vacation!

Here is the crossmember welded up. I always TIG everything but this time I figured I should use the MIG. I never really use it and would like to more. I am seriously considering getting a Miller 212 or 252. I actually enjoyed using the MIG.

My camera sucks. (yes, its still the waterfall camera still kicking.) Here is a close up bead. I thought it wasn't bad considering I don't MIG.

RE stuff should be here tomorrow.....

I have decided that I need some hot long arm action. I will incorporate Unibody stiffeners in my build. I also bought some 4.5" RE coils, 22" brake lines, and 4 RE 4.5-5.5 shocks. That should all be here on the 10th. Im still waiting on parts from extremecrawlers.com.

Here is how far I got today.

Here is the unibody stiffener. I am going to weld nuts to the inside on the sides and bottom to bolt the crossmember to. These took all of 15 minutes to make. I did everything free hand with my plasma cutter. I used a press to bend it up. I am going to use a hole saw to make holes to weld through and stitch the edges.

Next I took out the stock crossmember and started to build the replacement. Keep in mind there is no finish work. I didnt have my grinder and its all free hand plasma work. It will attach with 4 bolts on the bottom and 2 on the sides.

I still have to make end caps with holes for access and weld it up. Still deciding on TIGing the whole thing or just MIG it...

Here is how it fits. Nice and snug.

Next is a pleasant suprise. Well not totally but I didnt think it was that bad.

I have to pull the interior and get it all welded up. Thats gay.

This is what will be my long arms as soon as my Johnny joints, inserts and bushings get here. 2x.250 square for lowers and some 1.5x1.25 square for uppers.

Here is 100 ft of 1.75x .120 CREW that will end up as my bumpers.

Employees that helped today.

Here is the old shop whore. Still works like a champ.

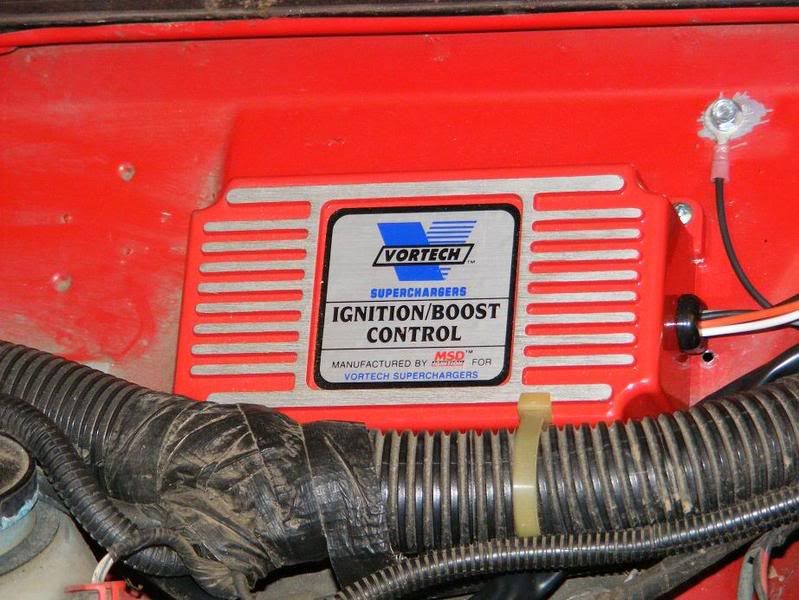

Ah and my new friend.

So plug weld the stiffeners in, make some control arms brackets when my joints come in and then finish the long arms. After that I will be cutting out my rockers and putting 2x6x3/16 in its place.

Had some time today to do a little more. I cut the holes for the unibody stiffeners to weld through. My hole saw has requested a vacation!

Here is the crossmember welded up. I always TIG everything but this time I figured I should use the MIG. I never really use it and would like to more. I am seriously considering getting a Miller 212 or 252. I actually enjoyed using the MIG.

My camera sucks. (yes, its still the waterfall camera still kicking.) Here is a close up bead. I thought it wasn't bad considering I don't MIG.

RE stuff should be here tomorrow.....

But now it works awesome.

But now it works awesome.

Comment