New Marlin Project.

Project Longbow.

When some of the engineers left Marlin most recently, a few of them sold some spare parts to myself and my boss, but they Gave me my newest project; A stainless Marlin 1895 receiver and floorplate. The engineer told my boss that it was a proofed receiver that he had been using for dimensions for the past few years and that he no longer had a use for it.

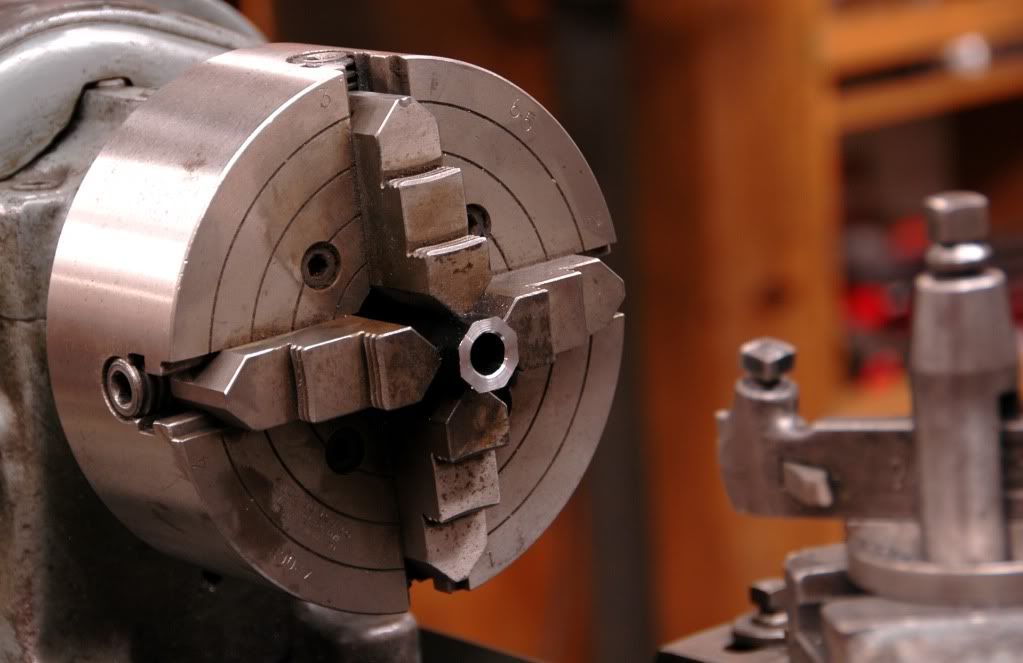

Well, I'm putting it to use now, problem being that I had to piece this thing together from scratch. I had the receiver and the floorplate, the hammer pivot screw and the bottom plate screw. I had a bolt, but missing the internals, so after digging around a bunch of Parts boxes, I was able to find the firing pin, firing pin block spring and whatnot and pieced one all together.

I quickly learned too that you could use a 336 extractor with the 1895, you just have to grind off that adverse nub so it will fit inside the receiver when locked up. It's quite a simple procedure and good to know if something ever happens to you extractor, you can easily replace it. The bolt dimensions are the same diameter wise, just the face of the bolt is custom fit for each caliber.

I obtained a barrel through Numrich, a 22" 45-70 Microgroove barrel and with some extremely minor fitting, I was able to torque the barrel right down to spec and it lines up perfectly. I took apart another 45-70 that was in the shop and just to inspect everything, I took some major internals and placed them within my own action and played around, making sure the bolt cycled fine and ejection worked.

Well, in the end those parts weren't mine, but a week later a member from Marlin Owners sent me a spare straight grip stainless Lever for nothing and with that, I fitted my new locking block to the gun and checked headspace. Everything was good to go.

Another member from Marlin owners also stopped by my shop and gave me a slew of parts including a hammer, forend cap and spring, buttstock and other good stuff.

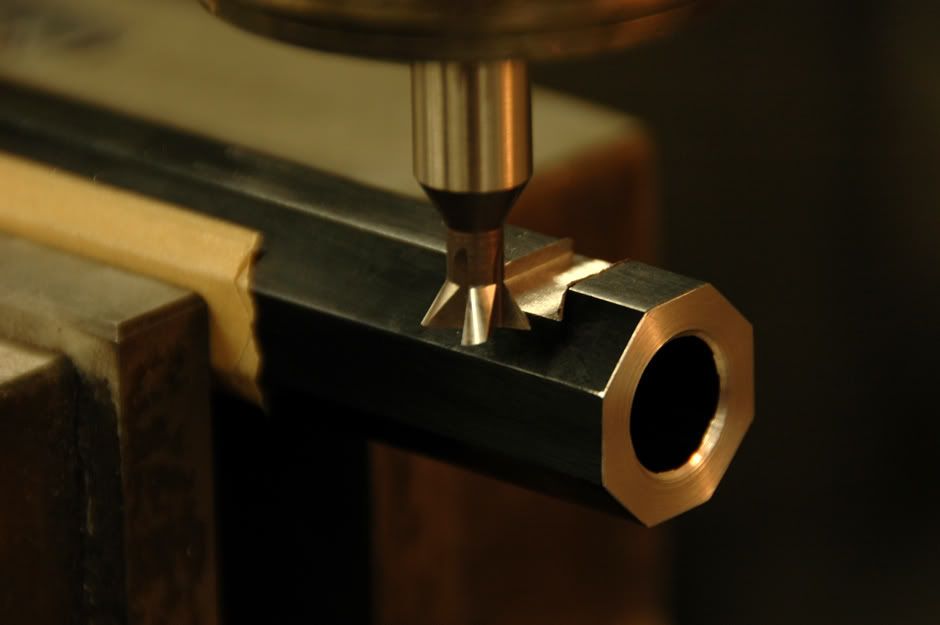

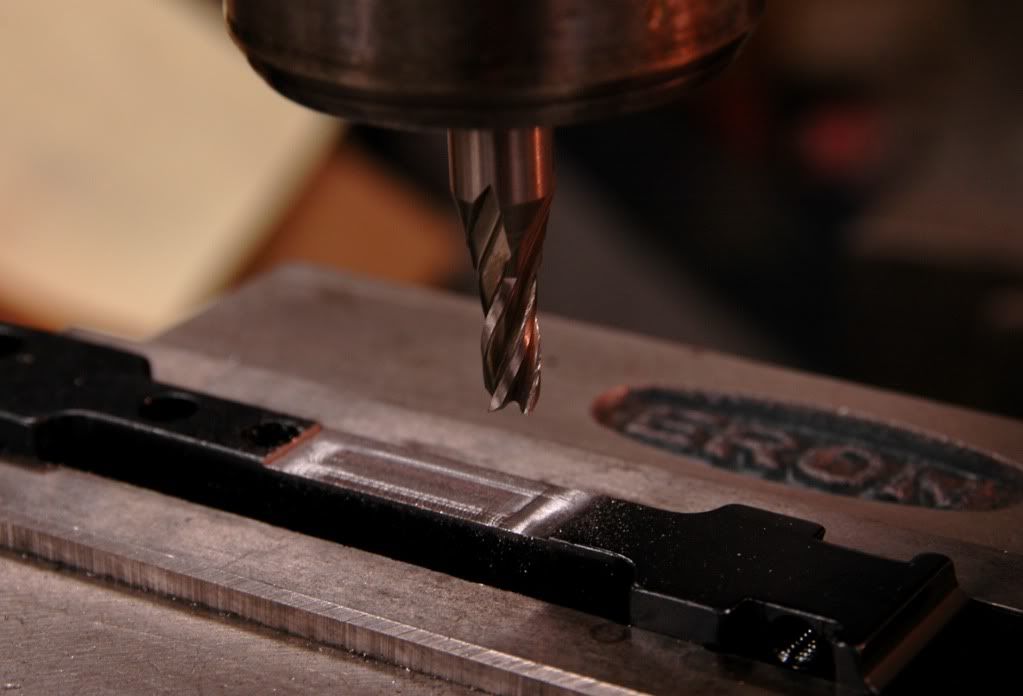

I also have a Magazine Tube from a Marlin 1895 cowboy gun, but being it is too long right now, I need to cut it down to match the 22" barrel that is on the receiver now. I still need the magazine cap retainer and mill a new slot into the barrel as I want a full length magazine tube under that 22" barrel.

Anyway, I was able to find an old forend to match the buttstock well enough and with some fitting, was able to get the new forend on.

This is all I have so far:

I will be leaving the Lever, receiver and the floorplate in the white as they are stainless, but everything else will be a matte blue. I think the contrast between the stainless and the blued parts will look awesome.

More updates as they come, which hopefully will be sooner than later.

Project Longbow.

When some of the engineers left Marlin most recently, a few of them sold some spare parts to myself and my boss, but they Gave me my newest project; A stainless Marlin 1895 receiver and floorplate. The engineer told my boss that it was a proofed receiver that he had been using for dimensions for the past few years and that he no longer had a use for it.

Well, I'm putting it to use now, problem being that I had to piece this thing together from scratch. I had the receiver and the floorplate, the hammer pivot screw and the bottom plate screw. I had a bolt, but missing the internals, so after digging around a bunch of Parts boxes, I was able to find the firing pin, firing pin block spring and whatnot and pieced one all together.

I quickly learned too that you could use a 336 extractor with the 1895, you just have to grind off that adverse nub so it will fit inside the receiver when locked up. It's quite a simple procedure and good to know if something ever happens to you extractor, you can easily replace it. The bolt dimensions are the same diameter wise, just the face of the bolt is custom fit for each caliber.

I obtained a barrel through Numrich, a 22" 45-70 Microgroove barrel and with some extremely minor fitting, I was able to torque the barrel right down to spec and it lines up perfectly. I took apart another 45-70 that was in the shop and just to inspect everything, I took some major internals and placed them within my own action and played around, making sure the bolt cycled fine and ejection worked.

Well, in the end those parts weren't mine, but a week later a member from Marlin Owners sent me a spare straight grip stainless Lever for nothing and with that, I fitted my new locking block to the gun and checked headspace. Everything was good to go.

Another member from Marlin owners also stopped by my shop and gave me a slew of parts including a hammer, forend cap and spring, buttstock and other good stuff.

I also have a Magazine Tube from a Marlin 1895 cowboy gun, but being it is too long right now, I need to cut it down to match the 22" barrel that is on the receiver now. I still need the magazine cap retainer and mill a new slot into the barrel as I want a full length magazine tube under that 22" barrel.

Anyway, I was able to find an old forend to match the buttstock well enough and with some fitting, was able to get the new forend on.

This is all I have so far:

I will be leaving the Lever, receiver and the floorplate in the white as they are stainless, but everything else will be a matte blue. I think the contrast between the stainless and the blued parts will look awesome.

More updates as they come, which hopefully will be sooner than later.

Comment