Well now that I've wheeled with you guys and have a bunch of other stuff I should be doing, I figure I will sit down and make a build thread.

Here is the thread I started back home

http://www.fingerlakes4x4.org/module...p?topic=2204.0

Ignore the parts where I whine about not having a garage and whatnot. I've come a long way since then. That's not to say I don't still have a long way to go, of course.

Cliff notes on that whole boring thread:

Specs:

About 4.5" lift or so

Midarm 3 link, driver's side upper

HD Offroad Mid stiffeners

33x12.50r15 grooved TSLs

3.55 gears (puke)

SYE using junkyard front shaft

OTK steering using weld in inserts and RHD drag link

Ballistic truss

LCA mounts flush with axle tubes

Teraflex trackbar shortened for OTA and bastardized with a 2" Ballistic Joint for double shear frame end

Aussie front

8.8 welded

3x5x3/16 tube rockers

Homemade bumpers

Rust

Dents

Rear bucket seats I forget about until people look back there

Not much has changed since the three link build I finished in the fall. It works great, I love it. Overall, I am very happy with the way it performs in 95% of all situations. But in my opinion, if it's not growing, it's dying. So for the short term (in between wheeling trips this summer/fall) I plan to:

Finish plating the unibody

Install the braided SS brake hoses I have for the front

Rear shocks through floor

Install larger tranny cooler

Here is the thread I started back home

http://www.fingerlakes4x4.org/module...p?topic=2204.0

Ignore the parts where I whine about not having a garage and whatnot. I've come a long way since then. That's not to say I don't still have a long way to go, of course.

Cliff notes on that whole boring thread:

Specs:

About 4.5" lift or so

Midarm 3 link, driver's side upper

HD Offroad Mid stiffeners

33x12.50r15 grooved TSLs

3.55 gears (puke)

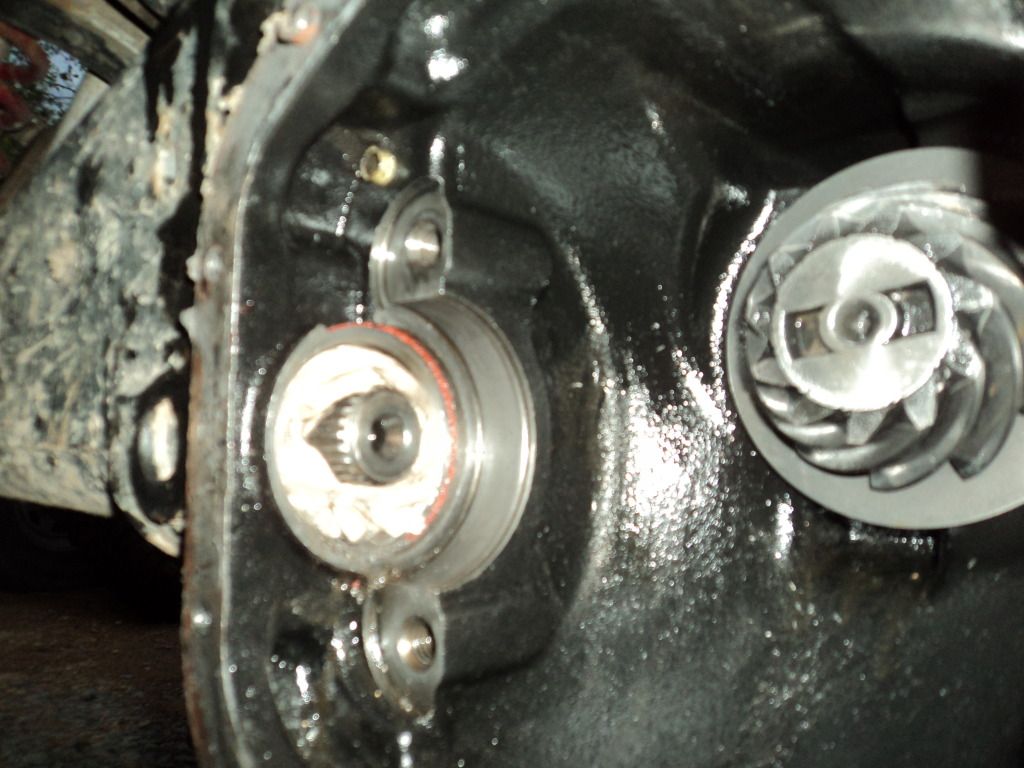

SYE using junkyard front shaft

OTK steering using weld in inserts and RHD drag link

Ballistic truss

LCA mounts flush with axle tubes

Teraflex trackbar shortened for OTA and bastardized with a 2" Ballistic Joint for double shear frame end

Aussie front

8.8 welded

3x5x3/16 tube rockers

Homemade bumpers

Rust

Dents

Rear bucket seats I forget about until people look back there

Not much has changed since the three link build I finished in the fall. It works great, I love it. Overall, I am very happy with the way it performs in 95% of all situations. But in my opinion, if it's not growing, it's dying. So for the short term (in between wheeling trips this summer/fall) I plan to:

Finish plating the unibody

Install the braided SS brake hoses I have for the front

Rear shocks through floor

Install larger tranny cooler

Vice President of Internal Affairs at Dirty Donny's House of Hookers

Vice President of Internal Affairs at Dirty Donny's House of Hookers

Comment