I keep losing coolant from my jeep. I'm trying to rule out a HG or even a head problem. Have all the parts laying around my house to build a leak down tester, i'm just half clueless on how to build one, because i've never used one.

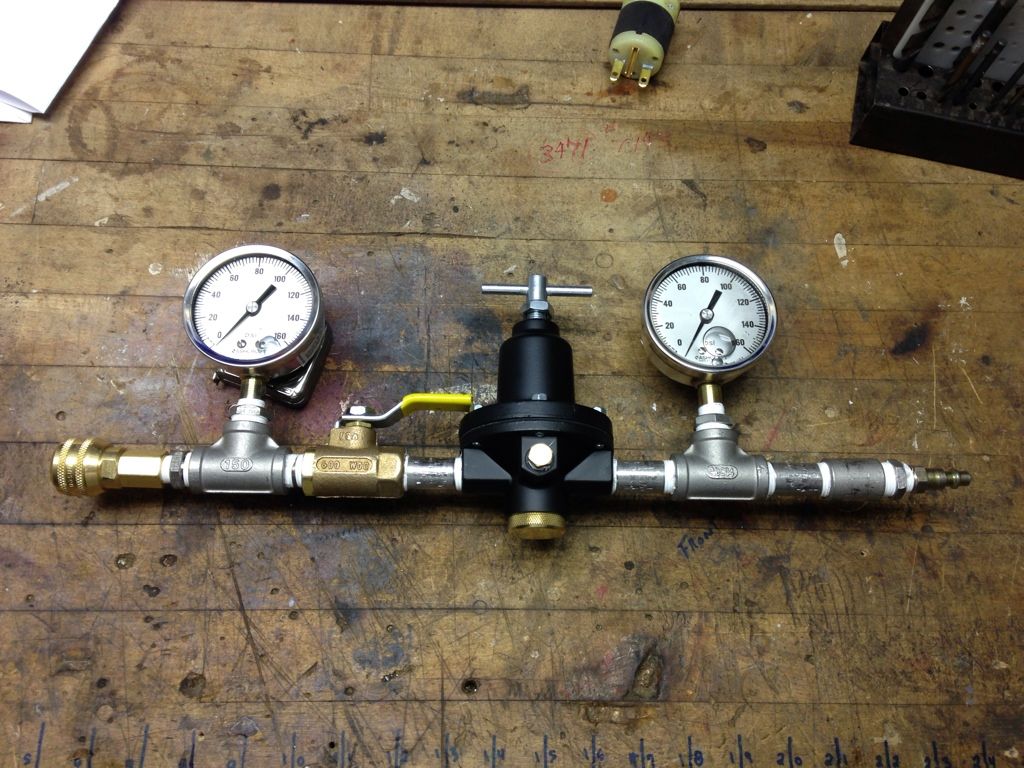

Can someone please tell me if i should be using option A (first picture) or option B (second picture)?.

I do not see anyone else with a ball valve in any of their leak down tester which is why i'm confused.

Here's my thinking;

Option A;

It's setup like everyone elses. First gauge (right of picture) shows the incoming air pressure from my air compressor, it goes through the pressure regulator and the second gauge shows the pressure it's reduced down to. Makes perfect sense.

I'm going to weld a 1/4" coupling to the third picture, and then thread a 1/4" NPT x 3/8" barbed fitting into it. Barbed side goes into 3/8 Tygon tubing, and on the other side is going to be another 3/8" barbed x 3/8" NPT fitting.

Option B;

Same as option A, except i added a ball valve after the pressure regulator. I was thinking that if there is no way to stop the flow of air, how the hell can i check the pressure leakage if the compressor just keeps pumping air in as it leaks out of the cylinder. Don't i have to put the cylinder to 100PSI, then close the ball valve, and watch the gauge to see if it drops? How can people use no ball valve?

Is my question even clear? Sorry for the ramble.

Can someone please tell me if i should be using option A (first picture) or option B (second picture)?.

I do not see anyone else with a ball valve in any of their leak down tester which is why i'm confused.

Here's my thinking;

Option A;

It's setup like everyone elses. First gauge (right of picture) shows the incoming air pressure from my air compressor, it goes through the pressure regulator and the second gauge shows the pressure it's reduced down to. Makes perfect sense.

I'm going to weld a 1/4" coupling to the third picture, and then thread a 1/4" NPT x 3/8" barbed fitting into it. Barbed side goes into 3/8 Tygon tubing, and on the other side is going to be another 3/8" barbed x 3/8" NPT fitting.

Option B;

Same as option A, except i added a ball valve after the pressure regulator. I was thinking that if there is no way to stop the flow of air, how the hell can i check the pressure leakage if the compressor just keeps pumping air in as it leaks out of the cylinder. Don't i have to put the cylinder to 100PSI, then close the ball valve, and watch the gauge to see if it drops? How can people use no ball valve?

Is my question even clear? Sorry for the ramble.

Comment