well new to this specific forum and following the advice of some people from here i'll start a build thread. i know most here don't like NAXJA but i have a thread there dating back to December 2012 that i'd prefer to not re post here so i'll just sum up a few things.

http://naxja.org/forum/showthread.php?t=1094425

bought a 99XJ that had a decent amount of stuff done to it by the prior owner Ryan Weaver who knows a few people in the XJ crowd.

from my original post December 30 2012

long arm installing

early Feb i was aimlessly wandering around the woods and power lines where we used to play paint ball

mid April i replaced the RE straight track bar that was on it, the himes were slopped out

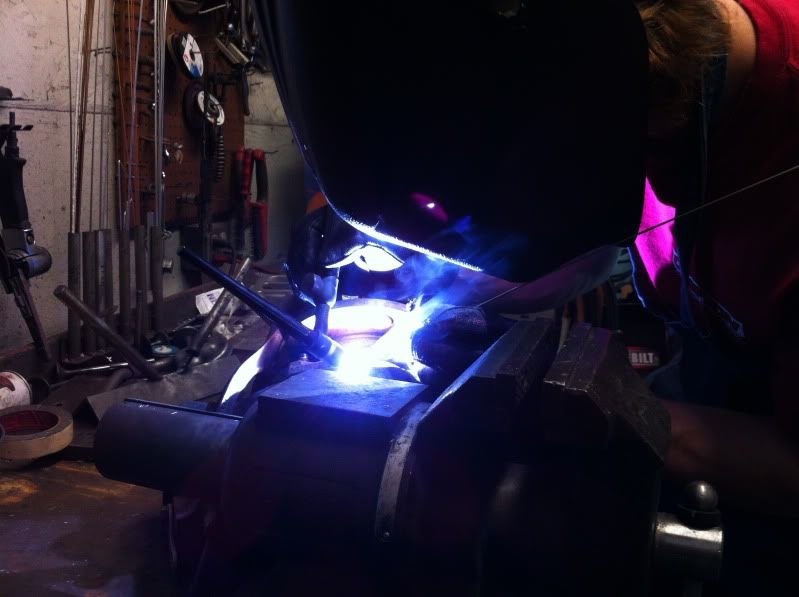

the fenders weren't trimmed as good as they should have been to clear the 35s so..... more fab work with the help of my bro.

it's ok, he's an engineer. he thinks he knows what he's doing

Before those pics were taken Alex is walking around looking for his welding jacket

"Hey is my Weldon jacket in my jeep or my other jeep?"

"You don't have shoes on" -me

"Oh"

(puts helmet on, tarts to weld)

random late night in mid may

finally NICE OUT!!!! took the doors off.... lost one pin and 2 spacers

picked this sweeeeeeeeeet low miles (85k) 4.0 up from a guy at work for some booze...... ya, about those "low miles" hahahah

some real nice looking bearings, think i'll just clean them up with some scotch bright and run em' again.

Brought the 4.0 to the shop, checked it.... Like everything is bad hahah.

2 bent rods, 2 five over pistons, bad crank, so this is gonna take a little longer

cleaned up the valves and reground them.

a few hours of playing with 16 holes and more best head grinding

block is ready for line hone, boring .20 over and final deck to even out the piston depth.

some axle work. stripped a stock D30 i picked up off CL for $50

now for the real "progress"? not sure if that's the right word.

custom jeep holder upper i made

little bit of axle building anyone?

the guy used one of those huge blue welder things with the gas tank, no idea why as i mean a $200 110V MIG from Harbor Freight with flux core does exactly the same thing..... right?

hover mode..... ON!!!

ANOTHER ass from Mass said he was coming to pick up the entire suspension and both axles so while i was out of state my bro pulled the rear and got it ready for him. he never showed up or responded to texts or calls. Hudson now has the axles for his build, kids got potential and isn't retarded. seems cool.

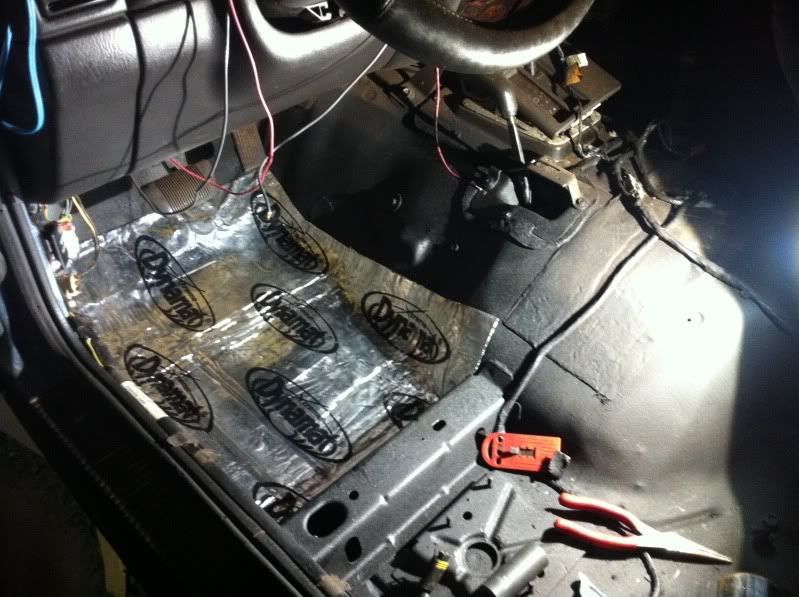

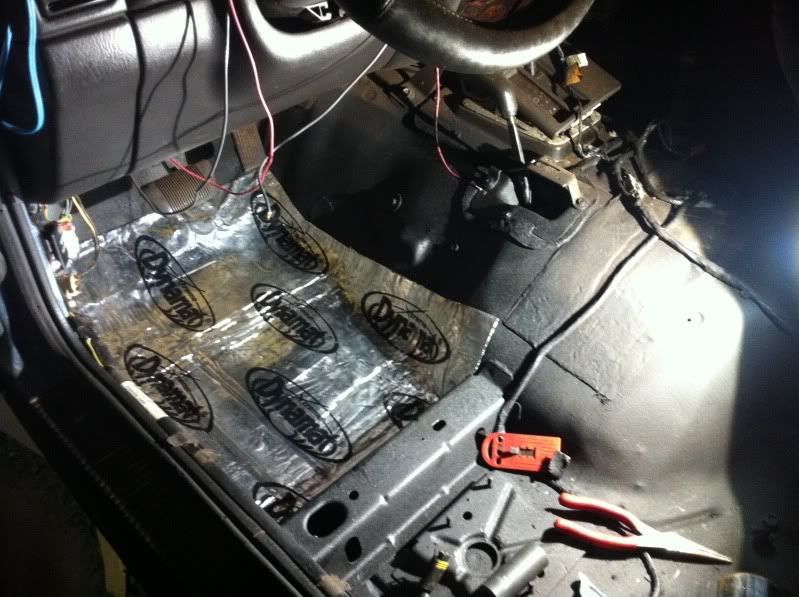

some rust on the floor, DAMMIT!

all patched up, welded, painted and then dynamatted

the passenger side will get the same thing done this weekend.

axle came back from the sand blast guy last week, painted it with some nice bed liner paint so it doesn't chip easy then put in the ball joins and upper Jonny joints thursday night.

http://naxja.org/forum/showthread.php?t=1094425

bought a 99XJ that had a decent amount of stuff done to it by the prior owner Ryan Weaver who knows a few people in the XJ crowd.

from my original post December 30 2012

99 XJ Limited, D44 rear, built up D30, 35s, bumpers, winch, rubicon express 5.5, 4.56s, Aussie lockers front/rear, WJ knuckles, custom high steering, labarron hood vents, and some other stuff i don't remember.

as it sat when i bought it

the front end is completely slopped out, did 2 bushings in last weeks snow storm out side. was going to upgrade to the adjustable rubicon lower arms but got in touch with a member here and picked up a pair of Clayton Long arms so those will be on soon.

spend all yesterday and night redoing the rear with new seals which were SHOT!! no rear brakes right now since the seals were so bad it messed them up but i'm not going to use them anyway.

already have parts to install.

Clayton long arms

Ford Exploder rear brake mod

52in LED Vision X light bar needs to get wired in

then just work the kinks out.

almost doesn't fit in the garage to work on it, i can only jack the wheels about 4in off the ground before the roof hits part of the storage racks we have.

and Bomb doggy Books hanging out while we do a tune up

plans.....

fender flairs

rock sliders

low pro roof rack to mount light bar to

clearance cut fenders more for the tires

get heated seats to work right

fab up a built in dog bed in the back for the pooch

as it sat when i bought it

the front end is completely slopped out, did 2 bushings in last weeks snow storm out side. was going to upgrade to the adjustable rubicon lower arms but got in touch with a member here and picked up a pair of Clayton Long arms so those will be on soon.

spend all yesterday and night redoing the rear with new seals which were SHOT!! no rear brakes right now since the seals were so bad it messed them up but i'm not going to use them anyway.

already have parts to install.

Clayton long arms

Ford Exploder rear brake mod

52in LED Vision X light bar needs to get wired in

then just work the kinks out.

almost doesn't fit in the garage to work on it, i can only jack the wheels about 4in off the ground before the roof hits part of the storage racks we have.

and Bomb doggy Books hanging out while we do a tune up

plans.....

fender flairs

rock sliders

low pro roof rack to mount light bar to

clearance cut fenders more for the tires

get heated seats to work right

fab up a built in dog bed in the back for the pooch

early Feb i was aimlessly wandering around the woods and power lines where we used to play paint ball

mid April i replaced the RE straight track bar that was on it, the himes were slopped out

the fenders weren't trimmed as good as they should have been to clear the 35s so..... more fab work with the help of my bro.

it's ok, he's an engineer. he thinks he knows what he's doing

Before those pics were taken Alex is walking around looking for his welding jacket

"Hey is my Weldon jacket in my jeep or my other jeep?"

"You don't have shoes on" -me

"Oh"

(puts helmet on, tarts to weld)

random late night in mid may

finally NICE OUT!!!! took the doors off.... lost one pin and 2 spacers

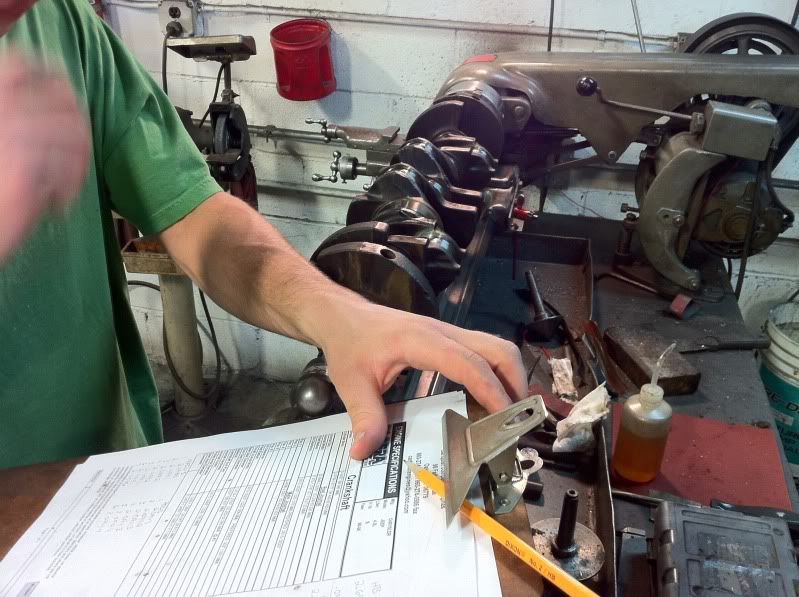

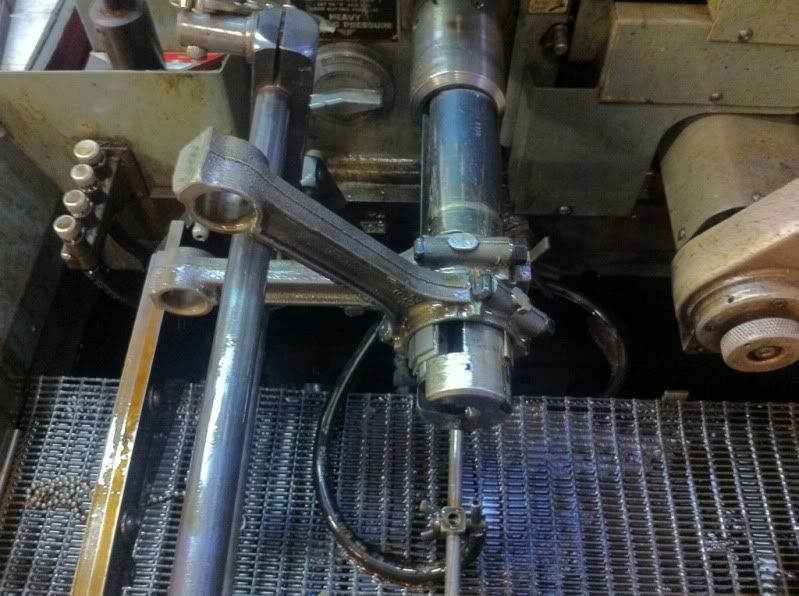

picked this sweeeeeeeeeet low miles (85k) 4.0 up from a guy at work for some booze...... ya, about those "low miles" hahahah

some real nice looking bearings, think i'll just clean them up with some scotch bright and run em' again.

Brought the 4.0 to the shop, checked it.... Like everything is bad hahah.

2 bent rods, 2 five over pistons, bad crank, so this is gonna take a little longer

cleaned up the valves and reground them.

a few hours of playing with 16 holes and more best head grinding

block is ready for line hone, boring .20 over and final deck to even out the piston depth.

some axle work. stripped a stock D30 i picked up off CL for $50

now for the real "progress"? not sure if that's the right word.

custom jeep holder upper i made

little bit of axle building anyone?

the guy used one of those huge blue welder things with the gas tank, no idea why as i mean a $200 110V MIG from Harbor Freight with flux core does exactly the same thing..... right?

hover mode..... ON!!!

ANOTHER ass from Mass said he was coming to pick up the entire suspension and both axles so while i was out of state my bro pulled the rear and got it ready for him. he never showed up or responded to texts or calls. Hudson now has the axles for his build, kids got potential and isn't retarded. seems cool.

some rust on the floor, DAMMIT!

all patched up, welded, painted and then dynamatted

the passenger side will get the same thing done this weekend.

axle came back from the sand blast guy last week, painted it with some nice bed liner paint so it doesn't chip easy then put in the ball joins and upper Jonny joints thursday night.

It seems like a waste.

It seems like a waste.

Vice President of Internal Affairs at Dirty Donny's House of Hookers

Vice President of Internal Affairs at Dirty Donny's House of Hookers

Comment