we have been taught to push the bead whenever possible.

Announcement

Collapse

No announcement yet.

Do my welds get an A?

Collapse

X

-

welds look good.

my take would be to turn amps up maybe 10-15 to burn hotter and not "hump" as much.

but as long as they hold then

helmet wise... I's got's a harbor frieght special auto darkening helmet that has done me well and cost $50-$60.2013 F150 fx4 (Tow Pig/DD)- 5.0 with the 3.73 option

2003 TJ Rubicon- 4.0/42rle/np241or

- 5.13's

- 3" Savvy/Currie suspension with acos

- 33†BFG KO2s

Comment

-

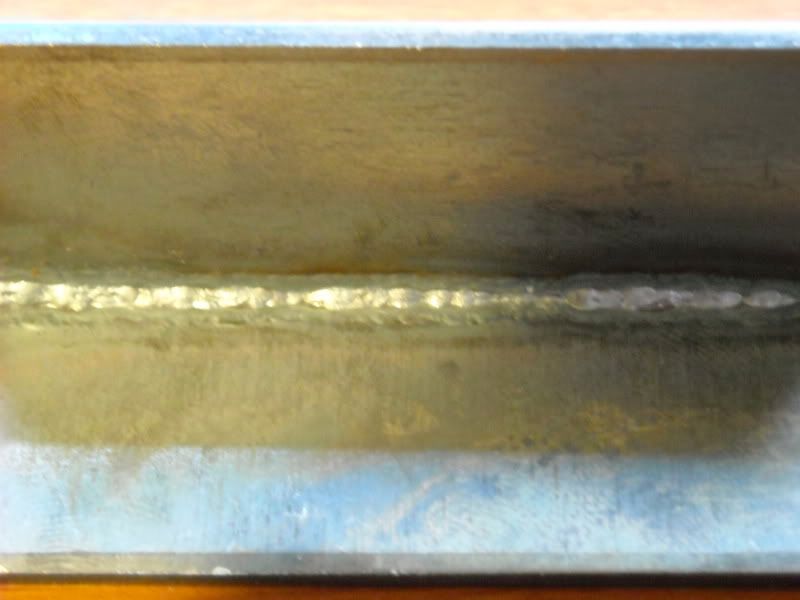

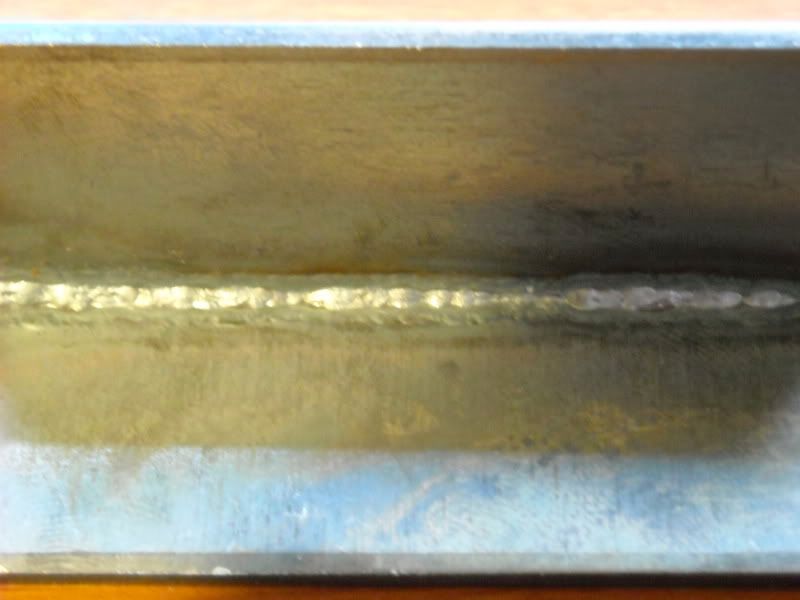

Started TIG welding tonight. Never touched one before or even seen it done in person before tonight. We dont have as many TIG welders as we do MIG's so we had to share, I only got to weld for maybe an hour from about midnight to 1am but this is what i ended up with.

the little dimple kinda in the middle there is where the filler rod stuck to the bead for a second.

penetration

I feel like i did real well for my first shot at it, and my instructors seemed to be pleased with what i was showing them.Jeep - every bump is a steering opportunity

Comment

-

i agree with this one... my welds look dirty, big, and excessive. at the same time you can beat the shit out of them and they will still work...JUST LIKE MAH JEEPOriginally posted by Buffalo Phil View PostThe question is Do they Hold?

OK, cosmetically they looks awesome, now take a hammer to it and smash the living fuck out of it. When I learned stick welding in school, they didn't give a fuck how it looked. Once you where done they put it in a vice and bent and smashed that thing all day until it broke. The longer it lasted, the better a grade you got.

I have no doubt those will hold, but I just want to see your welds really take the test, especially if you are going to apply those welds to jeeps, where they will most likely be structural. Watch your backhoe, I'm the John Deere man.

Watch your backhoe, I'm the John Deere man.

Comment

-

Very nice. If you are getting the filler sticking to the puddle its not hot enough. That is excellent work. Just work on TIG, that is what people pay for. Trust me.Originally posted by blakdot View PostStarted TIG welding tonight. Never touched one before or even seen it done in person before tonight. We dont have as many TIG welders as we do MIG's so we had to share, I only got to weld for maybe an hour from about midnight to 1am but this is what i ended up with.

the little dimple kinda in the middle there is where the filler rod stuck to the bead for a second.

penetration

I feel like i did real well for my first shot at it, and my instructors seemed to be pleased with what i was showing them.

Comment

Comment